Hardware¶

To build the hardware for this project you will need the following.

A microcontroller ESP32c3 pico.

A digital pressure sensor from the brand XIDIBEI (see aliexpress.com), select one that matches the range you want to measure.

PCB for mounting the components

Lithium battery compatible with the ESP32c3 pico (check the battery matches the connector, +/- pins)

DS18B20 temperature sensor (Needed for temperature data since the internal sensor is not accurate enough)

3.3k resistors for the temperature sensor data pullup

2 x Small switches for turning the device off and forcing configuration mode

Note

There is no need for pullups on the I2C bus since the XIDIBEI sensors already have internal pullups. These are added so that we can support other sensors in the future.

Note

The analog sensor support is preliminary and not fully tested. It has been designed to be used with a analog pressure sensor designed for 3.3V operation.

Note

ESP32c3 mini, ESP32s2 mini or ESP32s3 mini will also work but will require additional hardware such as LiPo charger and voltage divider for measuring battery. (The s2 does not support bluetooth). If you want to use any of these boards the pinout is the same.

Some boards only have one I2C hardware controller (ESP32s2 and ESP32c3) so here the second sensor uses a software based driver which is slightly slower.

Custom boards¶

Besides the standard boards listed here (which are tested and verified by me) there is also a possibility to add custom boards which are included in the builds and made available through this gihub repository. A list of these boards can be found here Custom boards. I cannot take full responsibility for these builds since I dont have access to these boards for testing.

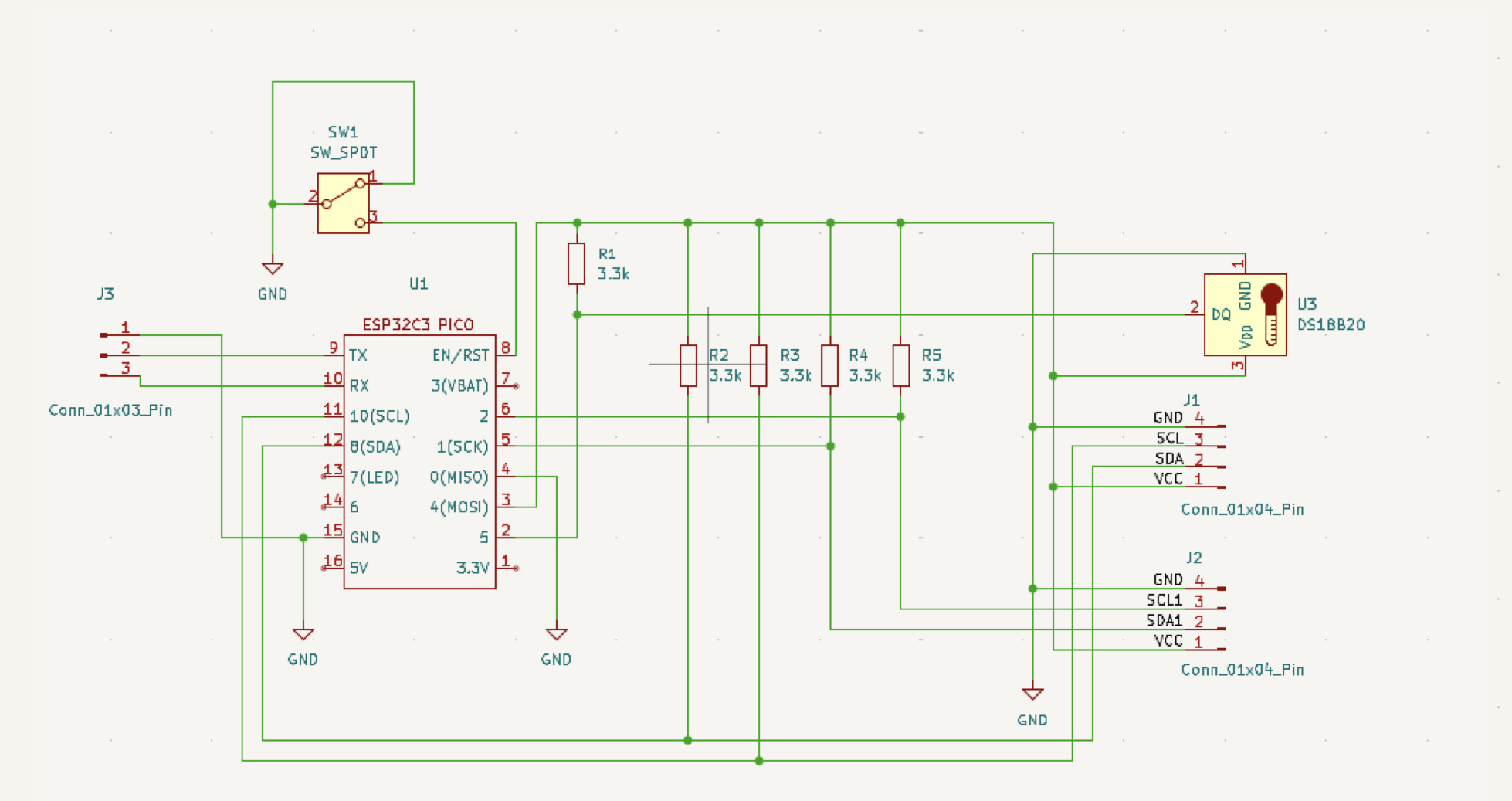

Schema for ESP32c3 pico¶

Building a device¶

Warning

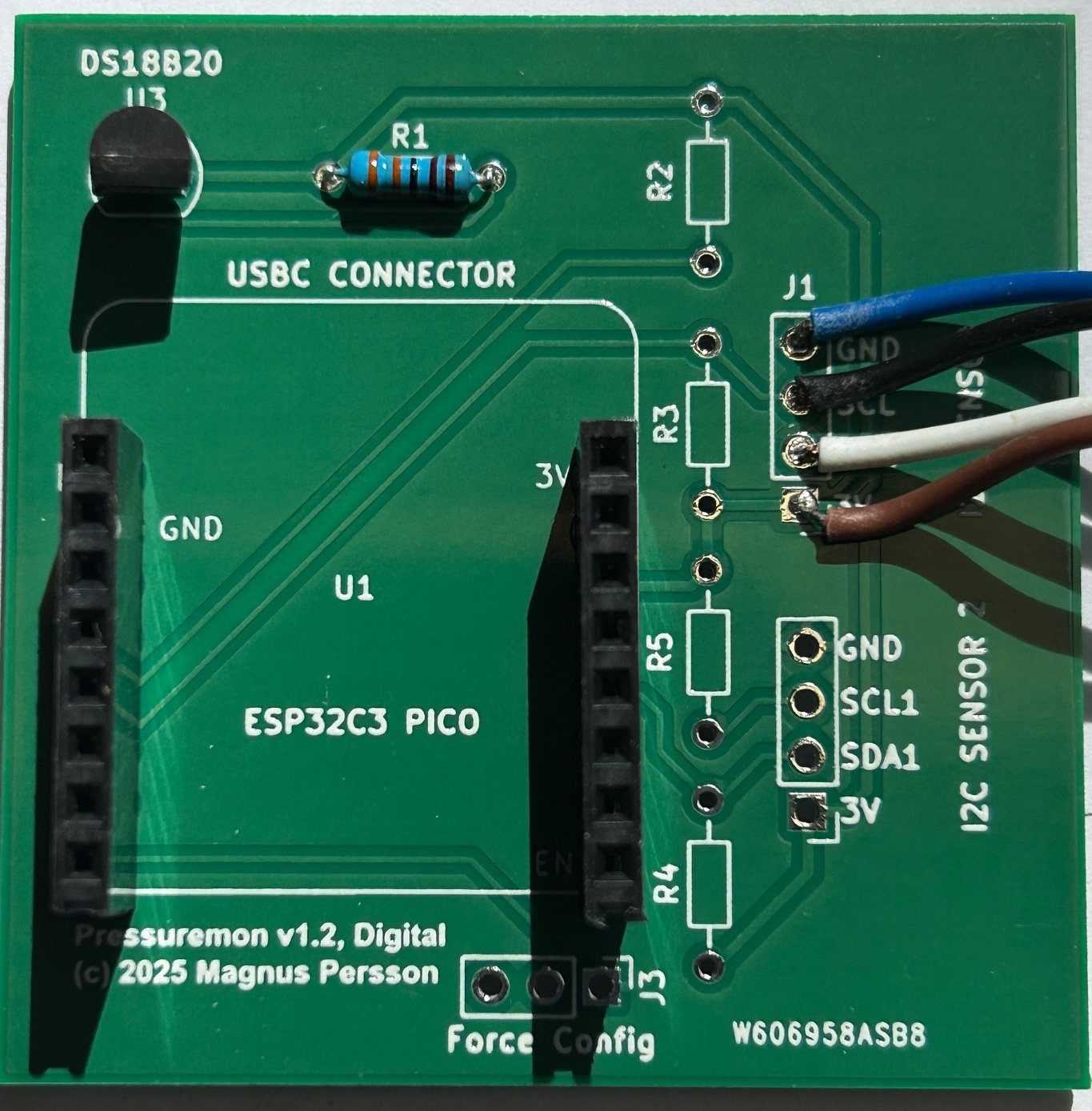

The images shown here for the v1.2 prototype pcb and does not include the switch. This is added to the next revision and I will update the images once these are manufactured.

First I would recommend to flash the esp board to make sure that that will work properly before mounting the rest of the components. To flash the pci you first need to place it in flash mode which is done by pressing the button marked 9 and then pushing the reset button and finally release the 9 button.

Once flashing has been done then do another reset so the esp will start up. You can then configure the wifi and connect the battery to see that you get a valid reading.

Next step is to put some solder on the jumper pads marked LED and VBAT on the back of the board. This will enable the battery sensor and LED. Without the VBAT jumper soldered there is no way to measure battery level.

Next step is to solder the other components on the board like the temperature sensor, temp sensor pullup resistor, pressure sensor and switch. I would also recommend to add some pins for the force config so that the device can be forced into configuration mode if needed.

Note

Make sure you use the pins for SENSOR 1 since the software does not yet support the second sensor.

Now you can mount the esp to the pcb and the build is done.